Making do

Every year, around this time, Luke and I brainstorm a long list of the things that we “need” for the cidery for the coming year. We call this our capex (capital expenditure) long list, or sometimes just the wish list. It can run the gamut from “forklift” to “better wifi” to “new bathroom.” (When we're done it reminds me of my 4 year old’s Christmas letter to Santa, which included a functioning steam locomotive). There are always a few moon shots thrown in, and sometimes they make it. The hard reality is, of course, that there is never enough time, energy or money to get everything on the list. Classic resource scarcity. Just like in any small business, there are hard trade-offs that need to be chosen from. But how?

Over the years, we developed a bit of a test for assessing the items on the wish list:

- Is not having this thing causing undue stress on the people making the cider?

- Is not having this thing affecting our ability to sell cider or provide a good experience to customers?

- Can we do without it or make do with what we already have?

The first two are pretty straightforward, and any items that trigger a yes tend to get moved forward without issue. It's this last question that is the kicker. Can we get by without it? Every time I look at that question I am reminded of an article I read in the Globe and Mail a few years ago, called “The Life Changing Magic of Making Do” by Benjamin Leszcz. Some of you may have read it. I repeat this passage in full here:

“Making do is a deeply pragmatic philosophy. It means asking of our things the only question we should ever ask of them: “Can you fulfill your intended use for me?” The answer – if we can be honest, and resist a moment of discomfort, inconvenience or boredom – is, extraordinarily often, yes. Making do is about taming the reflex to discard, replace or upgrade; it’s about using things well, and using them until they are used up. Taken literally, it simply means making something perform – making it do what it ought to do.”

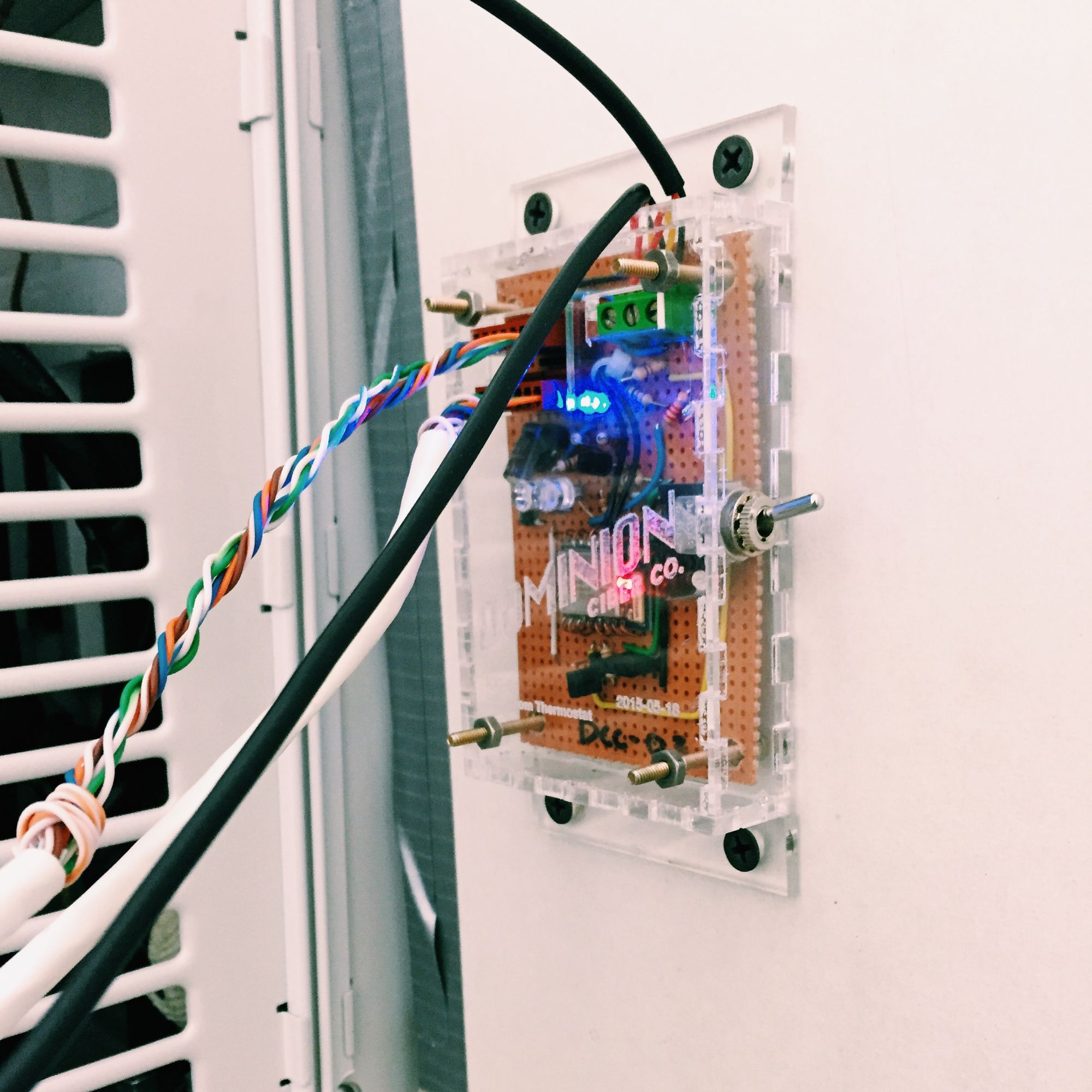

The whole article is excellent, but that sums it up and is an ethos that has become a part of the culture here at Dominion. As any visitor to the cidery has seen first hand, there are precious few shiny new things around. Almost all the tanks, pumps, glycol system, etc. were purchased used or were pressed back into use after being discarded by their original owners. Almost none of them were originally built for the purposes of making cider. Many of the pieces of equipment have now been repaired several times. Luke, one of the other partners at Dominion, is a master of using things well and making them perform.

While this may have started because we bootstrapped the company with our own savings back when we started in 2015, it has continued because that actually reflects who we are. It’s challenging but helps allocate resources to the areas of the company that truly deserve it. In addition, it feels deeply satisfying and a bit subversive to use elbow grease and ingenuity to make a product that can compete with those made in multi-million dollar facilities with state-of-the-art gear.

When you strip it all away, making cider is really a simple process. Good cider can, and has, been made with only basic technology for over a thousand years. Past cidermakers made do with horsepower, gravity and wood vessels. Making do with moderate wifi seems the least we can do.

Till next time

Mike